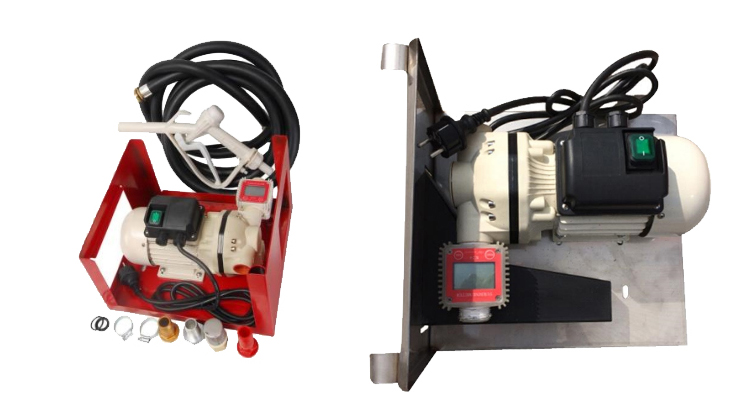

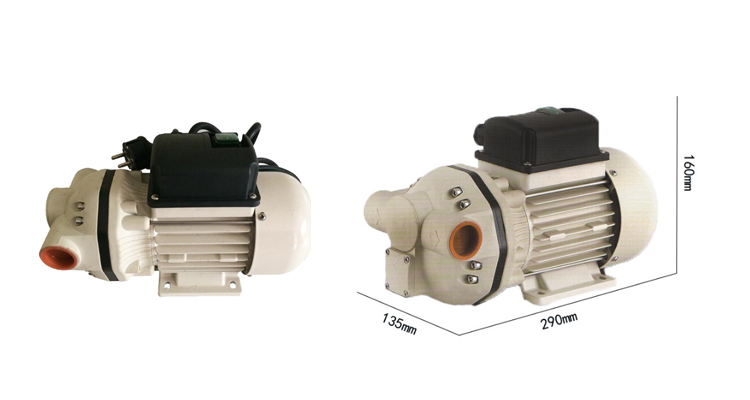

220 V Plastic Pump

Short Description

Features: acid and alkali resistant, corrosion resistant, and versatile. Can be used in food and beverage chemical chemistry, such as: chemical urea, detergent, diesel, engine oil, hydrochloric acid, sulfuric acid, nitric acid, etc. Note: This pump i..

Back:110 V DC pump

Next:220 V 380 V GOSLINE pump Gasoline explosion-proof pump

Tags:220 V Plastic PumpQuick Detail

Features: acid and alkali resistant, corrosion resistant, and versatile. Can be used in food and beverage chemical chemistry, such as: chemical urea, detergent, diesel, engine oil, hydrochloric acid, sulfuric acid, nitric acid, etc. Note: This pump is not resistant to high temperature, only normal temperature liquid (within 50 degrees), non-enhanced models can not be pumped hydrochloric acid, sulfuric acid, nitric acid, etc., after draining hydrochloric acid, sulfuric acid, nitric acid, etc., use water to prevent crystallization in the pump.

| Component | Flow Rate | Voltage | RPM | Power Watt | Pressure | Inlet/Outlet | Weight |

| Adblue Pump | 30L/Min | 12V, 24V | 2400 | 150W | 1.60BAR | 1" | - |

| Automatic Adblue Nozzle | 45L/Min | - | - | - | 0.20Mpa | Ø19 | 2.60Kg |

| Flow Meter | 40L/Min | - | - | - | 0.18Mpa | 1" | - |

1. Voltage: 12V, 24V

2. Flow Rate: 30 L/Min

3. Inlet/Outlet: 1"

4. Nozzle: Automatic Adblue Nozzle

5. Meter: Digital Flow Meter

6. Outlet Pipe: 4m

7. Inlet Pipe: 2m

First, the product introduction:

The RHJZ-40D computer micro-filler uses electromechanical integration equipment with advanced computer technology. Suitable for vehicles, oil depots, gas stations, construction sites, farms, factories, etc. Add liquid to vehicles or other equipment. This series of filling machines consists of motors, pumps, high-precision flow meters, sensors and computer controls. The computer controller uses imported chips. It has the characteristics of convenient carrying, high reliability, quick operation, simple maintenance, rich functions and easy to use. It shows the fill volume, amount and unit price. The quantitative and quantitative quantitative filling method is convenient for the operator to raise the vehicle and quickly. The refill data is displayed on the LCD screen, which is clear and beautiful. The RHJZ-40D computer micro-filler can enhance the reputation of the filling station, block management loopholes and improve operational efficiency.

Second, technical parameters:

1. Flow range: 10~60L/min;

2. Filling pipe length: 4M;

3. Measurement accuracy: 1.0%; 0.5%; 0.2%;

4, power: voltage: DC12V, DC24V, AC220V;

5, display digits: volume: 6 digits, amount: 6 digits, unit price: 4 digits;

6, the unit price setting range: 0~99.99 yuan;

7, the volume range: 0~9999.99L;

8. Amount: 0~9999.99 yuan;

9. Total accumulation: Volume: 9 digits: 11 digits;

10, suction: 3M;

11, head: 20M;

Third, the working principle:

Lift the filling gun and press the start button. The main board sends a start signal to the power drive board to start the motor. The motor drives the pump to run. The liquid first enters the filter element and the pump, and then enters the flow meter to push the piston to reciprocate, thereby driving the counter on the flow meter to generate a counting pulse signal to be sent to the main board, and the main board calculates the received pulse signal, and measures the amount and amount of the liquid. The liquid amount and the amount are displayed, and the liquid passing through the flow meter passes through the infusion tube, and the filling gun is output to the liquid receiving tube.

After the filling is completed, press the stop button, the main board sends a shutdown signal to the motor drive board, turns off the motor, puts the filling gun back into the bracket, and completes a filling operation.

Fourth, use and maintenance:

1. Maintenance and precautions:

(1) Open the filler door panel with the special key provided for easy installation and maintenance.

(2) After the preset measurement or amount of the keyboard, remove the filling gun. After 2 seconds, the motor will start, and the filling gun switch can be added to add, when added to the preset filling amount or amount, The motor is automatically turned off and the filling gun is no longer discharged.

(3) During the filling process, if the mouth of the filling gun hits the liquid level in the container, the self-sealing filling gun will be automatically closed and the liquid will be stopped. In order to prevent the liquid from overflowing from the container, it is wasteful.

(4) The filling machine should be kept clean at all times, and the impurities and impurities in the liquid tank and pipeline should be regularly removed.

(5) The filter should be cleaned frequently (once a week) and replaced if damaged.

(6) The blades of the pump should be inspected and cleaned regularly.

(7) The measurement accuracy of the meter should be regularly checked by the professional, and the liquid operator is not allowed to adjust it arbitrarily.

(8) The electrical must be disconnected from the power supply, and it is forbidden to electrify and repair.

Five, function introduction:

1. Convenient to carry: RHJZ-40D computer micro-filling machine is smaller than the ordinary filling machine, light in weight and easy to carry.

2. Accurate measurement: RHJZ-40D computer micro-filling machine can accurately calculate volume and amount.

3. The display is clear: the beautiful LCD screen displays the volume of the filling when the filling is completed, and the filling amount can be switched after the end of the filling. The display has an LED backlight that provides a long-lasting, clear and beautiful display, day or night.

4. Automatically accumulate the number of filling machines and the amount of filling: the total accumulated number is safe and reliable, and no one can change it. When it is added to the maximum value, it will be reset to 0.

5. Quantitative and non-quantitative: The quantitative filling method allows for filling according to the preset volume or amount value. When filling the quantitative value, the filling machine automatically ends. Non-quantitative filling allows for filling to any desired amount of liquid. When the liquid tank is full, the self-sealing gun automatically closes.

6. Self-sealing gun to prevent liquid overflow: Regardless of the filling method, the self-sealing gun automatically closes as long as the liquid tank is filled with liquid.

7. Unlocking input unit price: Only the liquid station supervisor holding the electric lock key can set the unit price to ensure the safety and accuracy of important data.

8. High reliability: The electronic part has fireproof and explosion-proof structure (need to be customized), safe and reliable, and the computer controller adopts high reliability design, which can work normally under severe voltage shortage and various harsh interference environments. Working temperature: -30 degrees ~ +85 degrees.

9. The computer control circuit adopts a functional module structure, providing high reliability and easy maintenance.