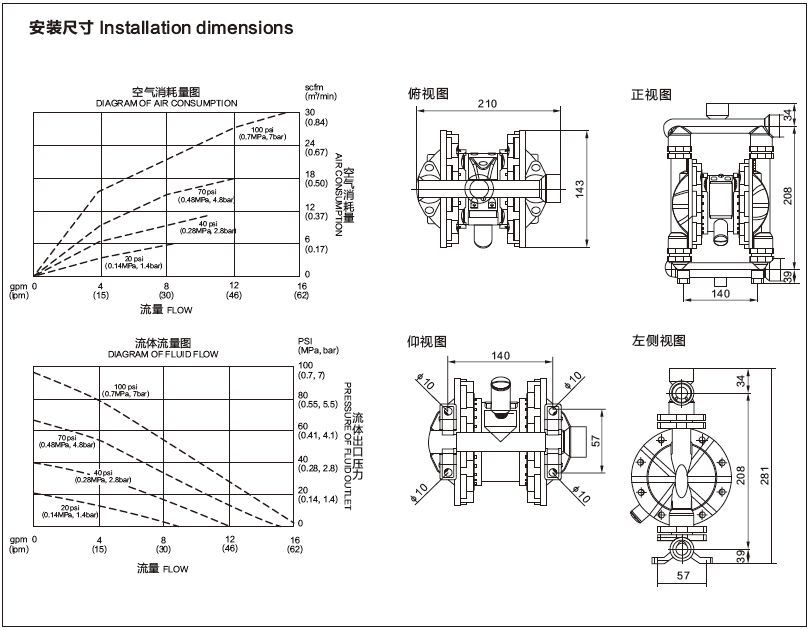

QBYK3-10/15 POLYPROPYLENE Pneumatic Diaphragm Pump

Short Description

OverviewQBYK3 is a highly efficient compact pneumatic diaphragm pump newlydeveloped through adopting most advanced reliable pilot-operated type airvalve. It is upgraded on the basis of traditional manufacturing technology.Operating efficiency is guar..

Back:QBYK3-20/25 CAST STEEL Pneumatic Diaphragm Pump

Next:QBYK3-10/15 STAINLESS STEEL Pneumatic Diaphragm Pump

Tags:QBYK3-10/15 POLYPROPYLENE Pneumatic Diaphragm PumpQuick Detail

Overview

QBYK3 is a highly efficient compact pneumatic diaphragm pump newly

developed through adopting most advanced reliable pilot-operated type air

valve. It is upgraded on the basis of traditional manufacturing technology.

Operating efficiency is guaranteed while its shape is optimized to shrink.

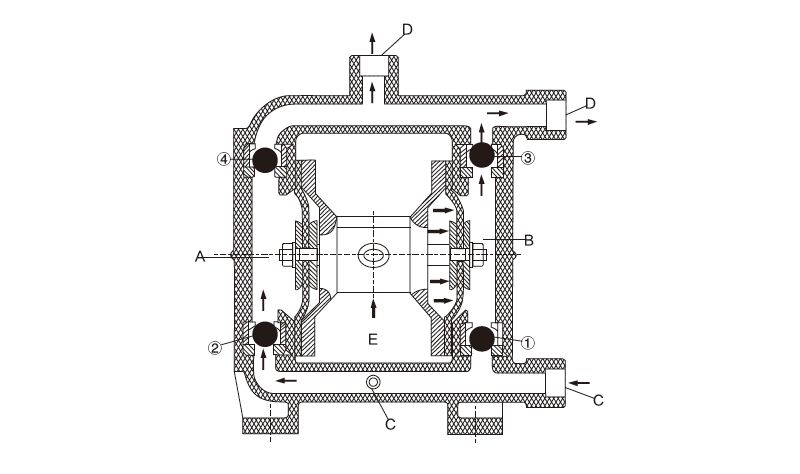

Working principle

There installs each diaphragm in both aligned working cavities A & B, which can be connected together with a central coupling lever. The compression air enters the air distribution valve from the air entrance of the pump, draw the compression air into one cavity through the air distribution mechanism, push out the diaphragm movement in the cavity. The gas in another cavity will be drained. Once reaching the stroke terminal, the air distribution mechanism will automatically draw the compression air into another working cavity, push out the diaphragm to move towards the opposite direction, so as to let the both diaphragms continuously reciprocate motion in synchronism.

The compression air enters the air distribution valve from E shown as the diagram, let the diaphragm piece move towards the right direction. And the suction force in A chamber lets the medium flow into from C entrance, push out the ball valve ② to enter A chamber, the ball valve ④ will be locked due to the suction force; The medium in B chamber will be pressed, push out the ball valve ③ to flow out from the exit D. Meanwhile, let the ball valve ① close, prevent backflow. Such movement in circles will let the medium uninterruptedly suck from C entrance and drain from D exit.

QBYK-10 |

||

| Max. Flow |

5.0 gpm(18.9 lpm) |

|

| Max. Working Pressure |

100psi(0.7MPa,7bar) |

|

| Fluid Inlet Size |

3/8 in.npt(f) |

|

| Fluid Outlet Size |

3/8 in.npt(f) |

|

| Air Inlet Size |

1/4in.npt(f) |

|

| Max. Suction Height (dry suction) |

8-10 ft.(2.5-3m) |

|

| Max. Permitted Grain |

0.06 in.(1.5mm) |

|

| Max. Air Consumption |

9.0 scfm |

|

| Every Stroke Flow |

0.006 gal.(23cc) |

|

| Every Reciprocating Flow |

0.012gal.(46cc) |

|

| Max. Reciprocating Speed |

Dry running |

320cpm |

| Wet running |

250cpm |

|

| Pump body structure materials: Cast steel, Aluminum alloy, Stainless steel, polypropyrene,polyvinylidene fluoride |

||

| Net weight:7kg for cast steel, 4kg for aluminum alloy, 7kg for stainless steel, 4kg for polypropyrene and 4kg for polyvinylidene fluoride |

||